New Era of Edible Oil Filling: Fully Automated Production Line Solution

Time:

2024-09-06

In today's rapidly developing food industry, edible oil, as an indispensable basic ingredient for home cooking, has a direct impact on consumers' health in terms of production quality and efficiency

In today's rapidly developing food industry, edible oil, as an indispensable basic ingredient for home cooking, has a direct impact on consumer health and market competitiveness in terms of production quality and efficiency. In order to meet the growing market demand, our company has carefully developed an efficient, intelligent, and environmentally friendly edible oil filling production line automatic equipment, aiming to create a comprehensive automation solution for customers from raw material processing to finished product packaging, leading edible oil production into a new era.

1、 Efficient automation to enhance production capacity

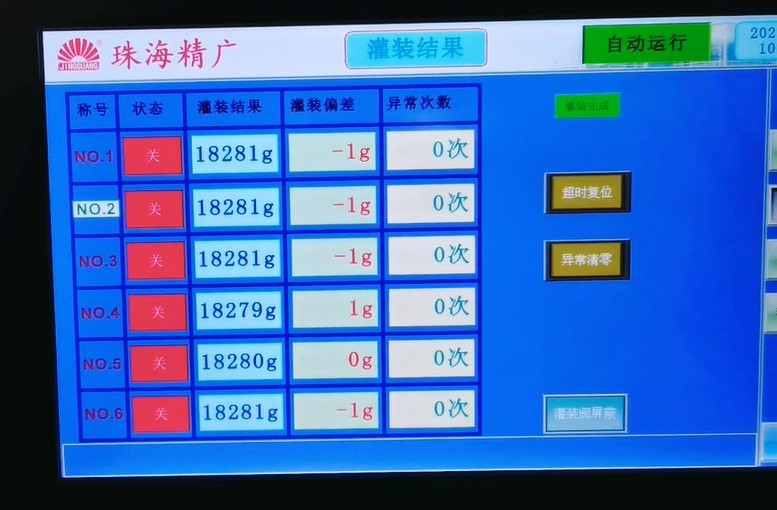

Intelligent recognition and precise measurement: Advanced sensors and high-precision metering pumps are used to achieve precise recognition and quantitative filling of different types of edible oils, with an error rate as low as millimeters, ensuring the accurate amount of each bottle of oil.

High speed filling system: Integrated with multi station parallel operation design, combined with servo motor drive, to achieve continuous and uninterrupted high-speed filling, greatly improving production efficiency and meeting the needs of large-scale production.

2、 Intelligent control, simplified operation

PLC intelligent control system: The core control system adopts a programmable logic controller (PLC) to achieve automated control and remote monitoring of the production process, with easy operation and low failure rate.

Human machine interface friendly: equipped with an intuitive and easy-to-use touch screen operation interface, supporting multilingual display, even non professionals can quickly get started and easily adjust production parameters.

3、 Quality assurance, safety and hygiene

Fully enclosed sterile environment: The production line adopts a fully enclosed design, combined with efficient filtration and sterilization systems, to ensure a clean and sterile production environment and effectively prevent oil contamination.

Material safety: Components that come into contact with oil are made of food grade stainless steel, which is corrosion-resistant, easy to clean, and meets international food safety standards to ensure the quality of oil products.

4、 Flexible customization to meet diverse needs

Modular design: The production line adopts modular design, which can be flexibly configured according to the specific needs of customers. Whether it is small-scale production or large-scale customization, it can be easily handled.

Diversified packaging options: Supports various specifications and materials of bottle types and packaging forms, such as PET bottles, glass bottles, iron cans, etc., to meet the needs of different markets and consumers.

5、 Energy conservation, environmental protection, and sustainable development

Energy optimization: adopting energy-saving motors and intelligent energy management systems to effectively reduce energy consumption and production costs.

Wastewater and exhaust gas treatment: Equipped with advanced wastewater and exhaust gas treatment systems, achieving green production, meeting environmental protection requirements, and helping enterprises achieve sustainable development.

Conclusion:

Our edible oil filling production line automatic equipment is gradually becoming the preferred choice for many edible oil production enterprises due to its high efficiency, intelligence, safety, and flexibility. We are committed to providing customers with one-stop solutions to help them stand out in the fierce market competition and create a brilliant future together. Choosing us means choosing a new era of more efficient, intelligent, and green edible oil production!

Related News

Share