Ensuring the accuracy of edible oil filling: analysis of key measures and strategies

Time:

2024-09-04

Ensuring the accuracy of edible oil filling machines requires starting from multiple aspects, including selecting suitable models, optimizing design and manufacturing, implementing strict quality control measures

The accuracy of edible oil filling machines is crucial for ensuring product quality, production efficiency, and consumer satisfaction. To ensure the accuracy of the edible oil filling machine, the following measures can be taken:

1、 Choose the appropriate type of filling machine

Different types of filling machines (such as piston type, gravity type, flow meter type, peristaltic pump type, etc.) have different working principles and precision control capabilities. When selecting, the appropriate machine model should be chosen based on the characteristics of the product, production requirements, and expected filling accuracy.

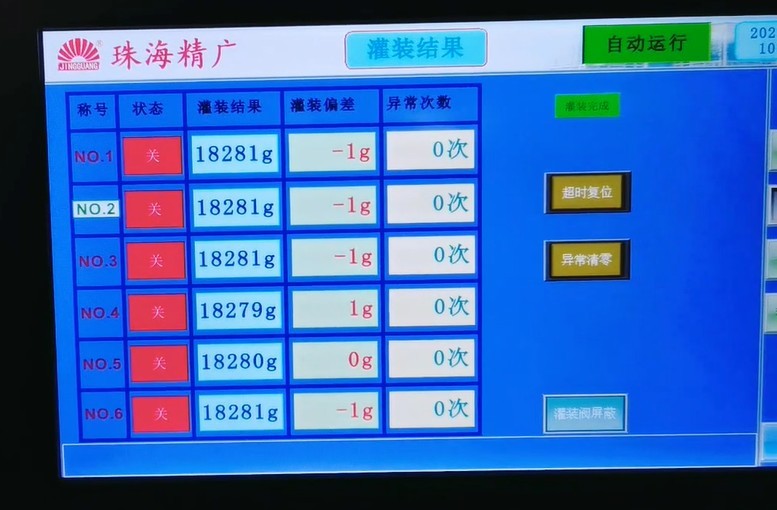

A good edible oil filling machine can achieve an accuracy of ± 1g

2、 Optimize the design and manufacturing of filling machines

High precision components: high-precision mechanical components and control systems, such as high-precision flow meters, precision sensors, etc., are used to reduce filling errors.

Stability design: Ensure the stability and reliability of the overall structure of the filling machine, and reduce the impact of mechanical vibration and other factors on filling accuracy.

3、 Implement strict quality control measures

Sensor monitoring: Install sensors at key positions of the filling machine to monitor real-time parameters such as flow rate, pressure, and temperature during the filling process, ensuring the stability and accuracy of the filling process.

Visual inspection: Introducing computer vision technology to detect the position, size, and sealing condition of bottles, preventing filling errors caused by improper bottle placement or sealing problems.

Weight detection: After filling is completed, the weight of the bottle is measured by a weighing device to confirm whether the amount of oil filled meets the standard. If the weight deviation exceeds the preset range, the system should issue an alarm and take measures.

4、 Regular calibration and maintenance

Regular calibration: Regularly calibrate the filling machine to ensure its accuracy and precision. The calibration process should be adjusted according to production requirements and environmental changes.

Maintenance: Carry out daily and regular maintenance work according to the maintenance manual provided by the equipment manufacturer, including cleaning, lubrication, inspection of seals and transmission systems, etc., to ensure the good operating condition of the equipment.

5、 Introducing intelligent and automated technologies

Intelligent control system: By introducing Internet of Things, big data, and artificial intelligence technologies, intelligent control and automatic adjustment of the filling process are achieved, further improving filling accuracy and production efficiency.

Data analysis and optimization: Utilize collected production data for analysis and optimization, identify key factors affecting filling accuracy, and take measures for improvement.

6、 Training and Personnel Management

Professional training: Provide professional training to equipment operators to understand the performance, operation methods, and maintenance requirements of the equipment, ensuring that they can operate the equipment correctly and proficiently.

Strict management: Establish strict operating procedures and management systems, standardize the behavior of operators, and avoid filling errors caused by human factors.

In summary, ensuring the accuracy of edible oil filling machines requires multiple aspects, including selecting suitable models, optimizing design and manufacturing, implementing strict quality control measures, regular calibration and maintenance, introducing intelligent and automated technologies, and training and personnel management. Under the joint action of these measures, the accuracy of the edible oil filling machine can be ensured to meet the expected requirements, thereby ensuring product quality and production efficiency.

Related News

Share